Join World's Fastest Growing B2B Network

CNC Gantry Machining Center-Features:

CNC Gantry Machining Center-High rigidity,Stability,Reliability

The gantry machining center has a compacts structure,wide capacity of machining,good rigidity and vibration resistance.It can do milling,boring,drilling,tapping and other machinings,It is mainly suitable for the precision machining of concave and convex molds in the mold industry,complex cavities and surfaces.It is also suitable for precision machining of large and medium-sized parts in industries such as general machinery,automobiles,aerospace,instrumentation,and textile machinery.

Typical applications such as precision machining of complex parts like molds,large plates,disks,and medium and large shells.

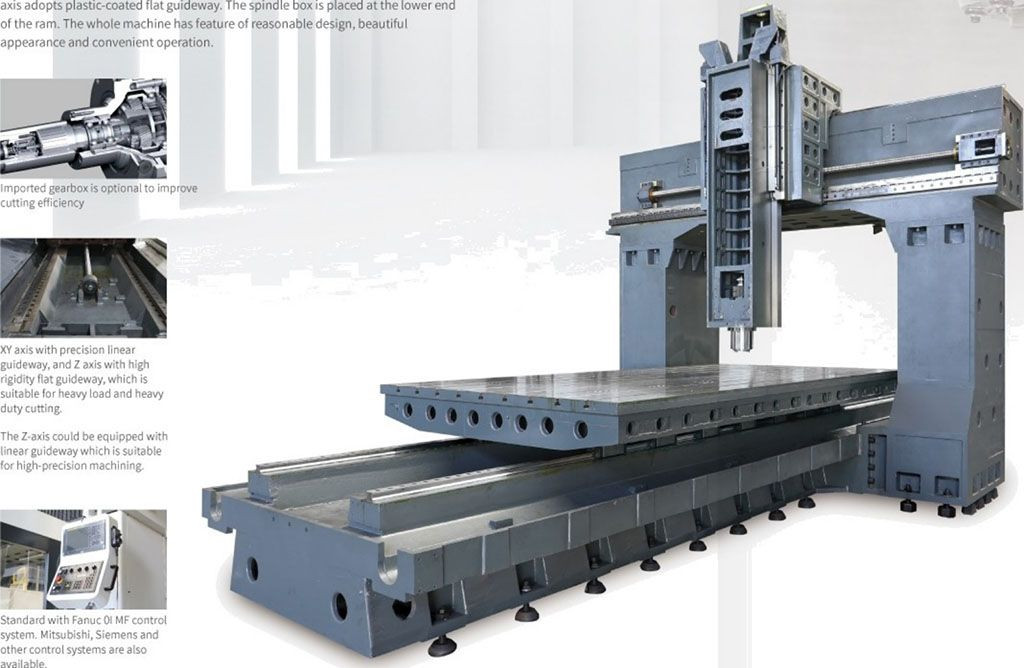

The whole machine adopts the gantry structure with moving table.The machine bed is fixed,worktable moves in the X direction on the bed,the ram moves in the Z direction on the slide seat,and the slide seat and ram move in the Y direction on the gantry beam.The X and Y axes adopt heavy-duty linear guideways,and the Z axis adopts plastic-coated plat guideway.The spindle box is placed at the lower end of the ram.The whole machine has feature of reasonable design,beautiful appearance and convenient operation.

Configuration

| No. | Name | Quantity | Remark |

| 1 | Fanuc 0i MF | 1 | |

| 2 | Remote | 1 | |

| 3 | Air gun / water gun | 1 | |

| 4 | Automatic lubrication | 1 | |

| 5 | Spindle blowing device | 1 | |

| 6 | Air curtain | 1 | |

| 7 | Standard accessories | 1 set | |

| 8 | Documents | 1 set | |

| 9 | Gear box spindle | 1 | Optional |

| 10 | 24T drum magazine | 1 | Optional |

| 11 | Right angle milling head | 1 | Optional |

No.332 Huanghai Road, Gangzha District, Nantong, Jiangsu, China.