Join World's Fastest Growing B2B Network

VegBox is a fruit and vegetable producer situated in the Wolayta zone in Ethiopia, 35km southwest of the city of Wolayta, Sodo. We are currently developing a 300ha farm for fresh fruit and vegetables. We started this project in December 2015 and the first plantation took place in March 2016. Our first harvest was in August 2016.

We have recently started production on 30ha of drip irrigated land that enhances our existing 30ha under traditional irrigation. Further to a wide range of vegetables (tomato, broccoli, cauliflower, chili, onion, okra, etc.) we have 25ha of papaya, mango, passionfruit and oranges under fruit.

We also produce Cassava without any addition of chemicals. Our own Casava production is then transformed into flour at Sodo.

Quality control in cassava flour production is crucial to ensure the final product meets safety and quality standards. Here’s a step-by-step outline of a typical quality control process:

1. Raw Material Selection

Inspection: Select high-quality cassava roots free from diseases and pests.

Testing: Check for appropriate moisture content and absence of toxins.

2. Processing

Peeling and Washing: Ensure cassava roots are thoroughly peeled and washed to remove dirt and contaminants.

Grating: Grate the cassava

3. Drying

Sun Drying: Dry the grated cassava to reduce moisture content to safe levels (usually below 12%).

Monitoring: Continuously monitor drying conditions to prevent microbial growth.

4. Milling

Grinding: Mill the dried cassava into fine flour. Ensure the milling equipment is clean and well-maintained.

Sifting: Sift the flour to achieve the desired particle size.

5. Quality Testing

Moisture Content: Test the flour for moisture content to ensure it is within safe limits.

pH Level: Check the pH to ensure it is within the acceptable range.

Nutritional Value: Analyze the nutritional content to meet specified standards.

Microbial Testing: Conduct tests for microbial contamination to ensure food safety.

6. Packaging

Sanitary Conditions: Package the flour in clean, dry, and airtight containers to prevent contamination.

Labeling: Properly label the packages with production and expiry dates, and storage instructions.

7. Storage and Distribution

Storage Conditions: Store the packaged flour in a cool, dry place to maintain quality.

Distribution: Ensure the distribution process maintains the integrity of the packaging and product quality.

8. Continuous Monitoring and Improvement

Feedback Loop: Collect feedback from customers and conduct regular audits to improve the quality control process.

Training: Regularly train staff on quality control procedures and updates in standards.

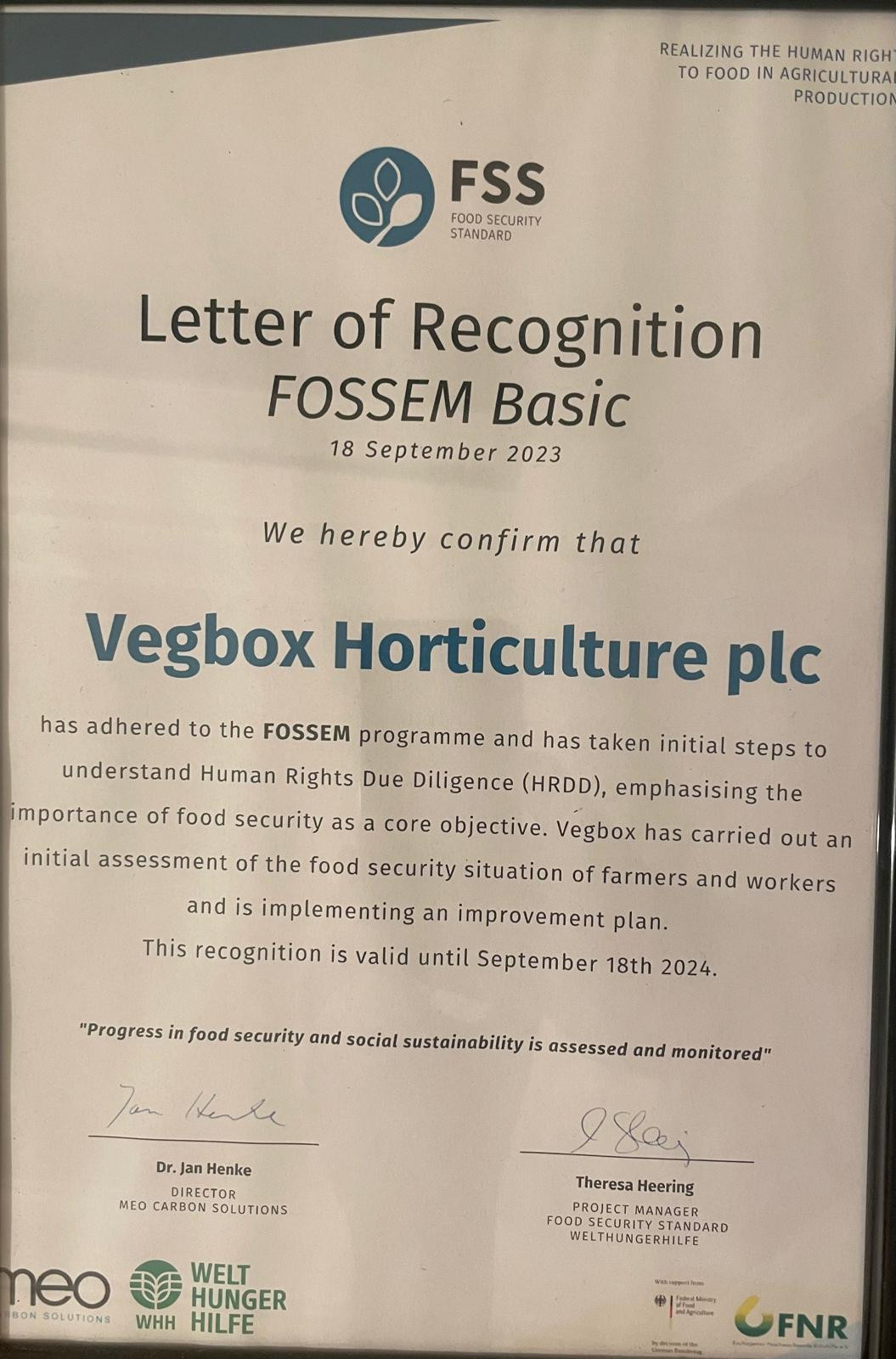

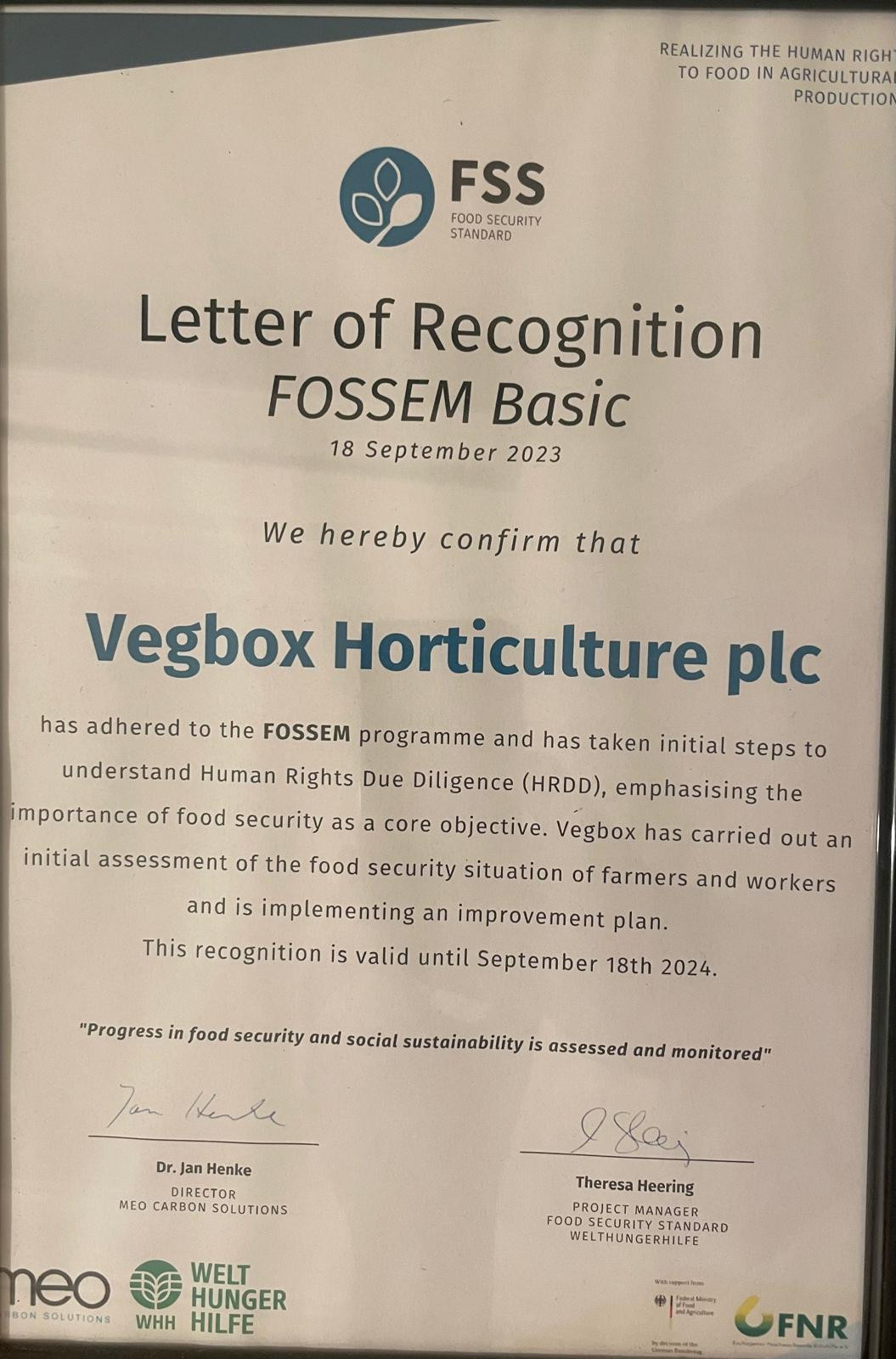

FOSEM

To fulfill the “Right to Food” and to achieve FSS certification, all criteria need to be complied with. However, complying with all requirements at once can be challenging for a farm and may take more time to achieve full compliance. In these situations, the FSS offers an alternative path: Food Security Sensitive Management (FOSSEM).

| Business Type | Supplier |

| Company | VegBox Horticulture PLC |

| Main Products | cassava flour |

| Website | vegboxplc.com |

| Established Year | 2018 |

| City / State | , Wolaita |

| Country/Region | Ethiopia |

| Address | Sodo, Tona Building |

| Location | Wolaita, Ethiopia |

| Factory Size | |

| Total QC Staff | 2 |

| Total RND Staff | |

| Number of Production Lines | |

| Annual output | |

| Average Lead Time | 30 |

| Total Revenue | |

| Export Percentage | |

| Nearest Port | DJIBOUTI |

| Overseas Office | Neue Mainzer Str. 26 60311 Frankfurt, Germany |